Fiber-optic Based Distributed Atomic Absorption Spectroscopy for Film Growth Monitoring

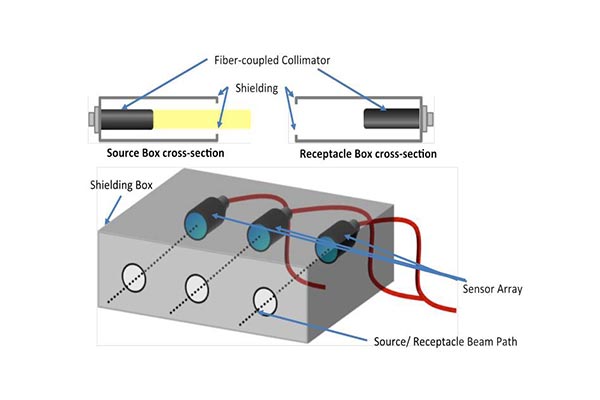

AccuStrata is utilizing its expertise in thin film growth monitoring and optical system design to create a breakthrough AAS product, installable on a variety of PVD systems, to provide accurate and reliable deposition rate measurements for dynamic feedback control of the PVD systems. The system comprises two major parts – a reconfigurable hardware module located outside the PVD and a portable fiber-optic-based distributed monitoring frame installed in the area surrounding the deposited substrate. AccuStrata’s two-part design eliminates issue associated with system size and allows for virtually any number of monitoring light sources to be implemented within the system. The second component, a prefabricated and optically aligned frame structure, eliminates errors associated with window deposition, changes in chamber pressure, and other environmental factors. The unique shielding design will virtually eliminate contamination of the optics resulting in very low long-term drift.

The system will measure the atomic flux density in a mesh of 3×3 for 9 regions near the substrate and provide real-time information about the vapor source operations and their fluctuations. The system will accommodate up to 6 different fiber-coupled hollow-cathode light sources with capability of monitoring two material concentrations simultaneously. Based on its existing software platform, AccuStrata will develop user-friendly software for real-time process analysis, which will further be developed during subsequent Phase II to create close-loop in-situ AAS process control system. The unique fiber optic design provides for superior protection from coating on system components and easy reconfigurability, facilitating subsequent commercialization in any field where PVD processes are involved (visual optics, aerospace, medical, automotive, etc.).