Virtual Coater: The world’s first commercial software for simulation of thin film properties and equipment configurations

Simulate your PVD coater and coating properties before you spend money on equipment and R&D

Virtual Coater™ is developed by Innovative Coating Solutions (ICS) Namur, Belgium in collaboration with University of Namur, Belgium

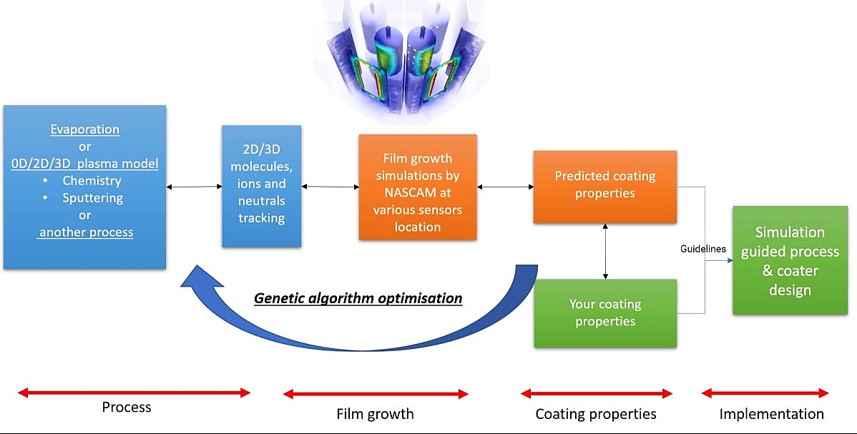

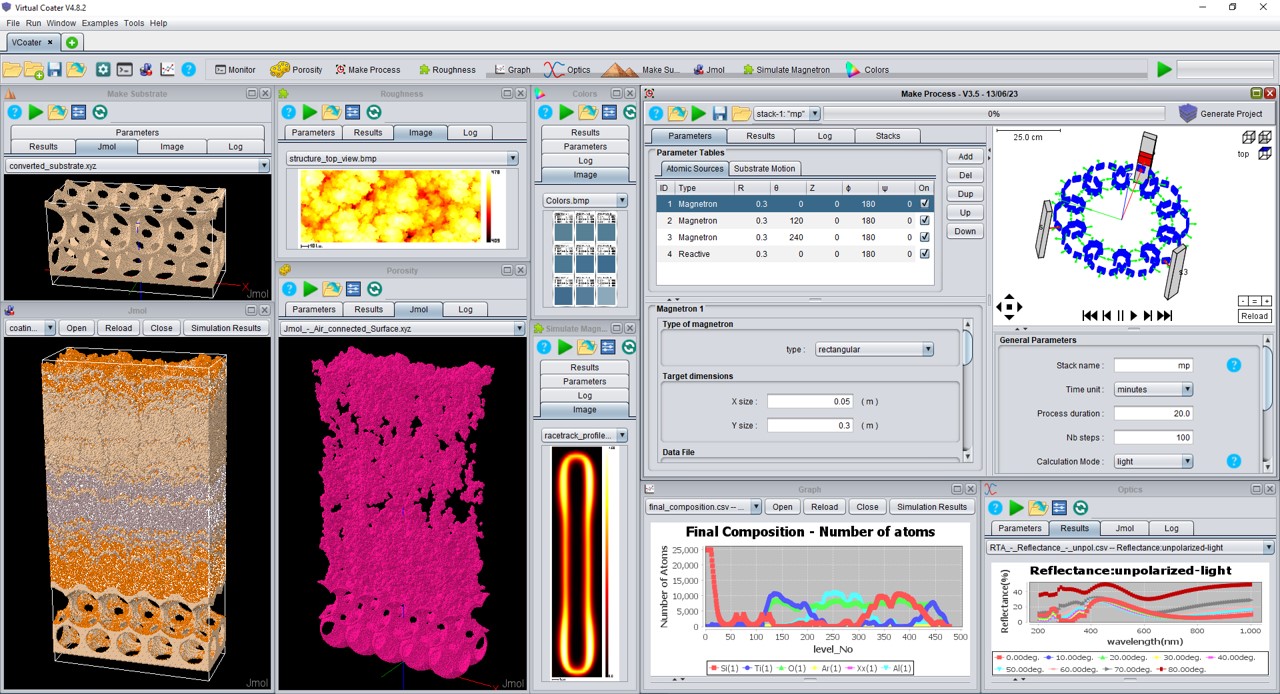

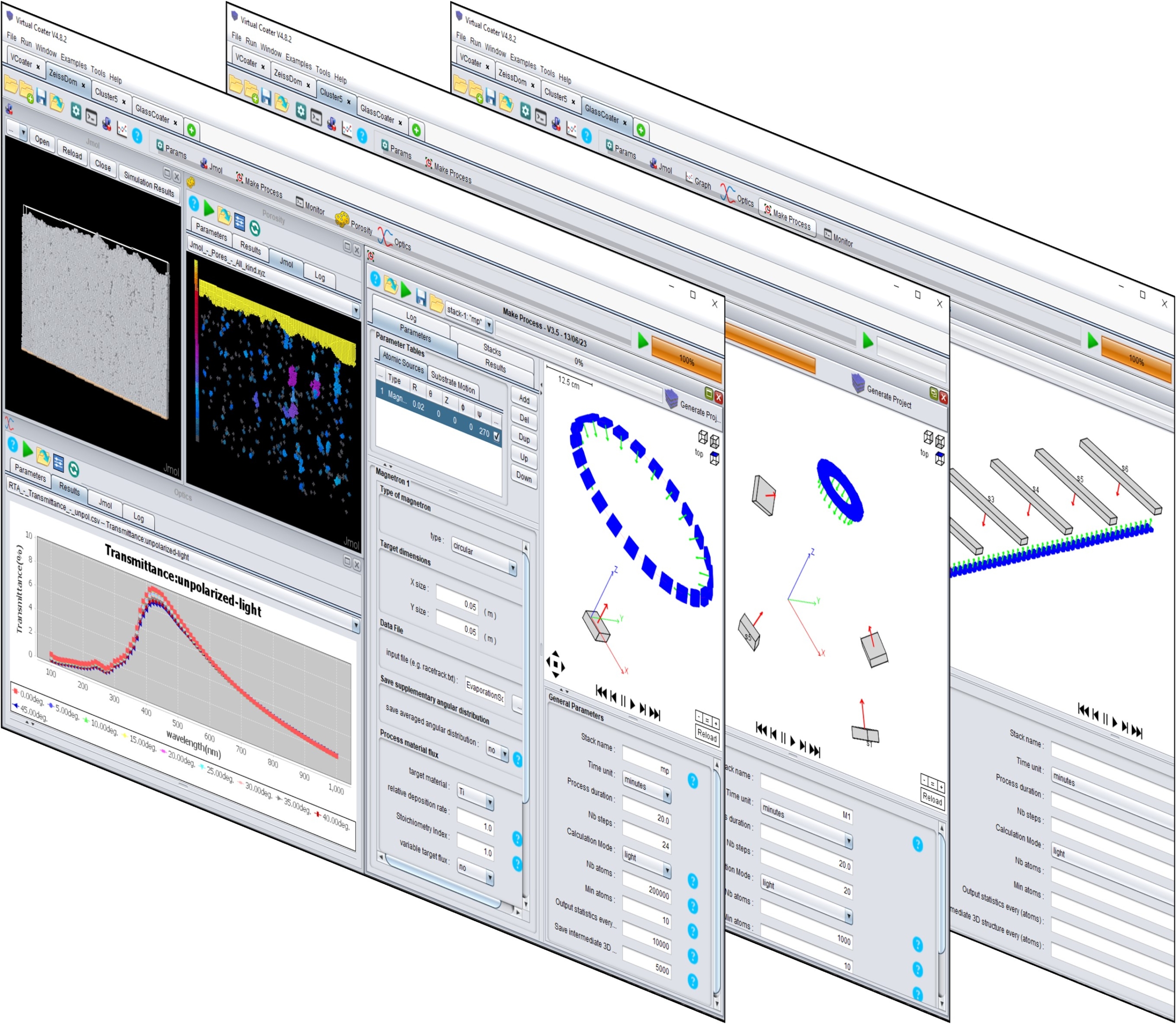

Virtual Coater™ is a new software tool for modeling and simulation of PVD/HiPIMS coater geometries, substrates and process conditions for rapid process optimization and achieving desired coating properties at lowest cost.

A holistic digital twin for your coating processes and equipment

- Find the key process parameters to improve process, enhance machine configuration and lower product cost.

- Improve configuration of coating process in PVD/HiPIMS.

- Achieve the best quality or new functionality of your coatings.

- Design the perfect coater for the best productivity and quality of your product.

- Deposit/modify the surface of a composite, nanocomposite or powder?

- Improve coating uniformity on parts with complex shapes or motions during PVD.

What is Virtual Coater™

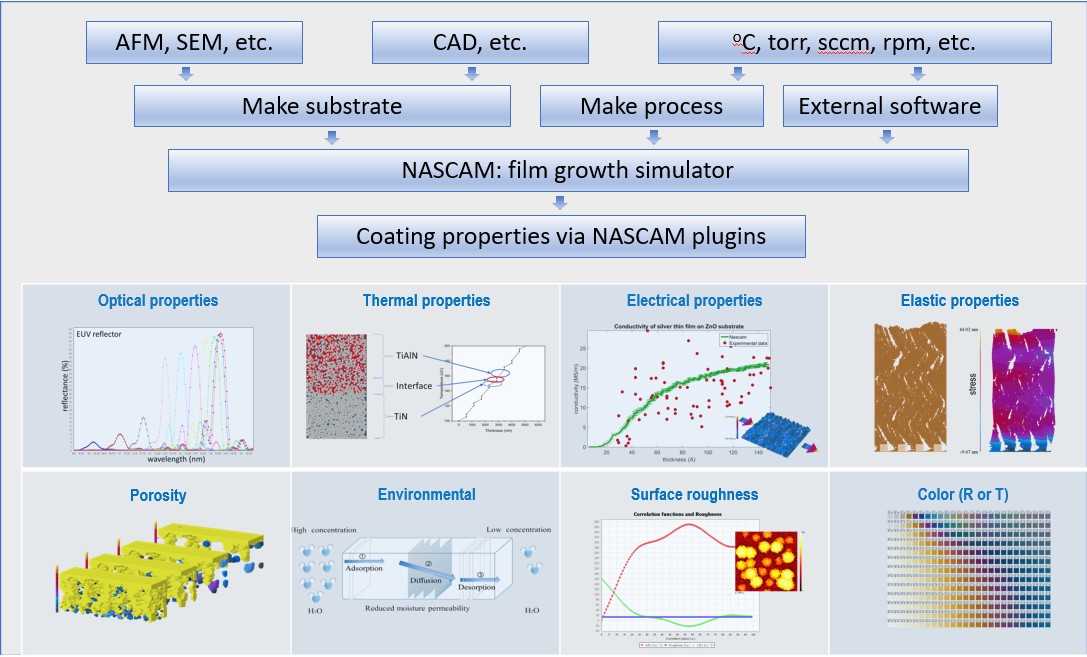

- Atomistic film growth simulator of film composition, morphology, porosity, roughness, etc., as function of coater geometry, material characteristics, process parameters, substrate shape

- Simulate a variety of PVD processes and configurations.

- Change equipment configurations, substrate’s properties / motion and process conditions and improve coating quality.

- Make educated technology and executive decisions and lower risk prior to spending $$$ on purchasing equipment or process development.

- Discover new configurations and process conditions and tune coating process to lower product cost without expenditures on material, labor and R&D effort.

- Save $$$ of development cost, new equipment design or new process development.

- Custom simulation, consultancy and training provided as off-site service.